The right tape stays put

If you’re a low voltage/datacom installer, electrician, security integrator, or professional A/V installer, you probably have some experience with worksite labels not holding up on the job. Maybe they’re peeling, fading, and costing you time and money you can’t afford.

Fortunately, the solution to these issues is simple. Use the right tape for the right job. Not all industrial labels are created equal, and it’s essential to choose the correct one for your specific task. Choose the wrong one, and you’ll be disappointed. Choose the right one, and the label won’t just stay on until you physically peel it off. It will also:

- Fit and look great (even on cable wraps, flags, and rough surfaces)

- Resist fading from UV, chemicals, heat, water, abrasion, and more

- Save you time and money on relabeling

- Keep you organized and compliant

So, how can you find the best tapes for the many different applications on your jobsite? Brother has you covered. But first, let’s reinforce why traditional and run-of-the-mill options won’t cut it on industrial jobs.

The problem with handwritten labels

If you’re still labeling your jobsite using handwritten labels, you’re not alone. In fact, a staggering 50% of respondents in a recent survey of datacom and electrical professionals reported using handwritten labels1. The pitfalls of this approach are clear – and similar to the problems that come from picking the wrong tape.

Labels aren’t always legible. The need to re-label increases labor hours and costs. Plus, the lack of accurate labeling can lead to troubleshooting errors and downtime – something that is especially detrimental to data centers and other environments where uptime is critical.

For industrial professionals who want to be proud of a job well done (while also avoiding customer complaints and tedious trips back to the jobsite), using the right tapes is critical. Discover everything you need to know about which tape to use for your every job and application.

How to pick the right tape for your application

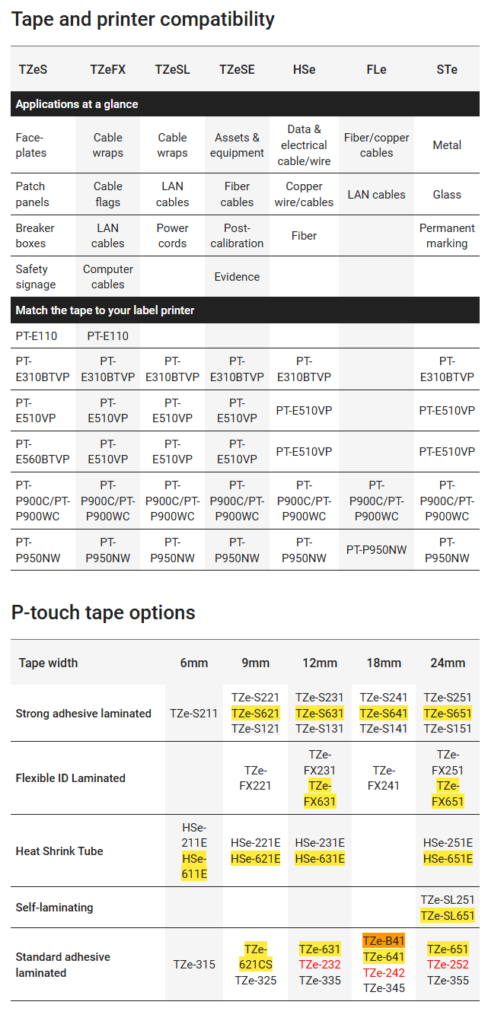

At Brother, we have tried and tested tapes made to work exactly where you need them. From extra-strength tape perfect for powder-coated surfaces to flexible ID tape ideal for cables and wires, we’ve engineered a wide variety of tapes made to withstand the wide range of conditions you need them to perform in:

Strong Adhesive Laminated Tape

This extra strength adhesive tape is perfect for rough, uneven, and powder-coated surfaces. In independent lab testing, Brother Strong Adhesive tape showed three times the adhesive strength on average over our Standard Adhesive (TZe) tapes. This makes TZeS tapes ideal for long-term labeling – even in the harshest conditions and especially on textured surfaces.

Flexible ID Tape

Made for industry professionals that need reliable wire and cable ID options, this tape can also be used to mark pipes or other smaller cylindrical shaped items of 3mm or more. Where other tapes may peel over time, our TZeFX stays put!

Self-Laminating Tape

If you need long-term reliable identification of cables, TZeSL tapes are a great option. With our cost-saving TZeSL line of tapes, text is laminated during printing – which means 24mm tape works for wrapping around even larger diameter CAT6A cables.

Tamper Evident Tape

This black on white tape features our exclusive laminated tape process with an added security bonus. If the label is removed, a checkerboard pattern appears on both the item and the tape – giving you the clear sign of tampering. Also, the label won’t adhere again after being tampered with. This line of tapes is perfect for asset marking or ensuring unauthorized individuals can’t interfere with panels and covers.